Latest Judgement on Inventive Step of Semiconductor Patent: Dow Global Technologies and Rohm and Haas’s Equipment Patent Was Declared Invalid

Date: 31 August 2022

【Volume 90】

The China National Intellectual Property Administration (CNIPA) issued Patent Invalidation Decision No. 56742 on June 23, 2022, declaring patent application No. 201510512498.4 held by Dow Global Technologies LLC and Rohm and Haas Electronic Materials CMP Holdings, Inc. invalid. Throughout the trial, the CNIPA employed a relatively strict standard regarding the determination on whether the experimental data in the specification supports the technical effects. Data that does not include and present all the limitations of a claim might not suffice as proof of the claimed technical effect.

Case Fact

Dow Global Technologies LLC and Rohm and Haas Electronic Materials CMP Holdings, Inc. filed a patent application No. 201510512498.4 "POLYURETHANE POLISHING PAD" (the patent at issue) to CNIPA on August 19, 2015, and was granted on Fabruary 28, 2020. Thereafter, natural person WANG, WEI-SIOU filed a patent invalidation request, believing all claims of the patent at issue do not involve an inventive step. The CNIPA issued Patent Invalidation Decision No. 56742 on June 23, 2022, declaring all claims of the patent at issue invalid.

Technical Analysis of the Patent at Issue and Exhibit 4

The patent at issue provides a planarizing polishing pad having accelerated metal removal rates with low defect levels. Claim 1 writes:

“A polishing pad suitable for planarizing at least one of semiconductor, optical and magnetic substrates, the polishing pad comprising a cast polyurethane polymeric material formed from a prepolymer reaction of H12MDI/TDI with polytetramethylene ether glycol to form an isocyanate-terminated reaction product, the isocyanate-terminated reaction product having 8.95 to 9.25 weight percent unreacted NCO, the isocyanate-terminated reaction product being cured with a 4,4′-methylenebis(2-chlororaniline) curative agent, the stoichiometric ratio of the NH2 from the 4,4′-methylenebis(2-chlororaniline) curative agent to the NCO from the isocyanate-terminated reaction product being 102 to 109 percent, the cast polyurethane polymeric material, as measured in a non-porous state, having a shear storage modulus, G′ of 250 to 350 MPa as measured with a torsion fixture at 30° C. and 40° C. and a shear loss modulus, G″ of 25 to 30 MPa as measured with a torsion fixture at 40° C. (ASTM D5279) and the polishing pad including hollow microspheres having an average diameter of 20 μm and the polishing pad having a porosity of 20 to 50 percent by volume and a density of 0.60 to 0.95 g/cm3.”

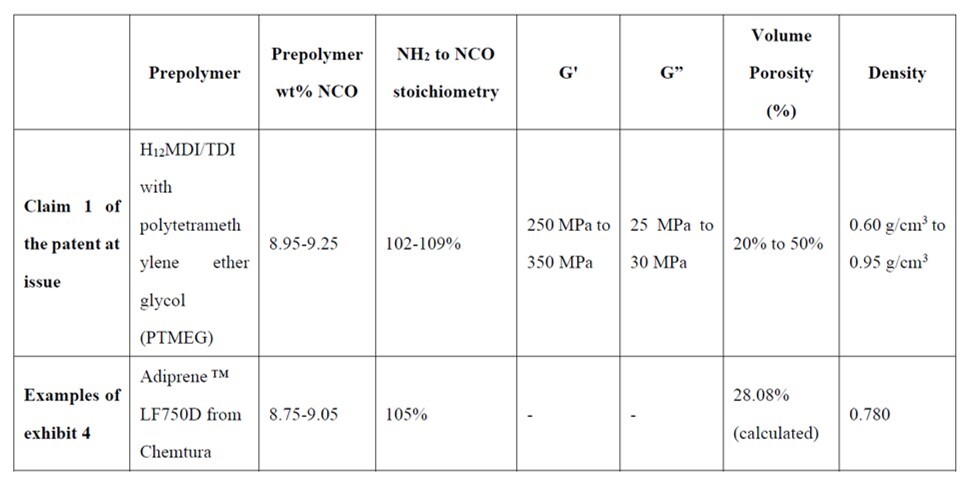

Exhibit 4 (CN101077569A, owned by Rohm and Haas Electronic Materials CMP Holdings, Inc.) discloses that "there is a desire for polishing pads suitable for polishing oxide/SiN with an improved combination of planarization and defectivity polishing performance." Example 1 of exhibit 4 set forth the preparation of the polishing pad materials, along with a performance evaluation. Values taken from the examples of exhibit 4 and claim 1 of the patent at issue are shown in the table below:

Accordingly, the differences between the patent at issue and exhibit 4 are:

(1) Prepolymer material: The patent at issue uses H12MDI/TDI-PTMEG to form an isocyanate-terminated reaction product (i.e., Adiprene ™ L325), while exhibit 4 uses Adiprene™ LF750D from Chemtura, a formulation containing a blend of TDI and PTMEG.

(2) Exhibit 4 does not disclose G′ and G′′ measured in a non-porous state, as specified in claim 1 of the patent at issue.

Opinion of the CNIPA

The CNIPA holds that the two distinct technical features can be easily conceived by a person skilled in the art pursuant to the disclosure of exhibit 4. Hence, the patent at issue is not inventive. The detailed reasons are as follows:

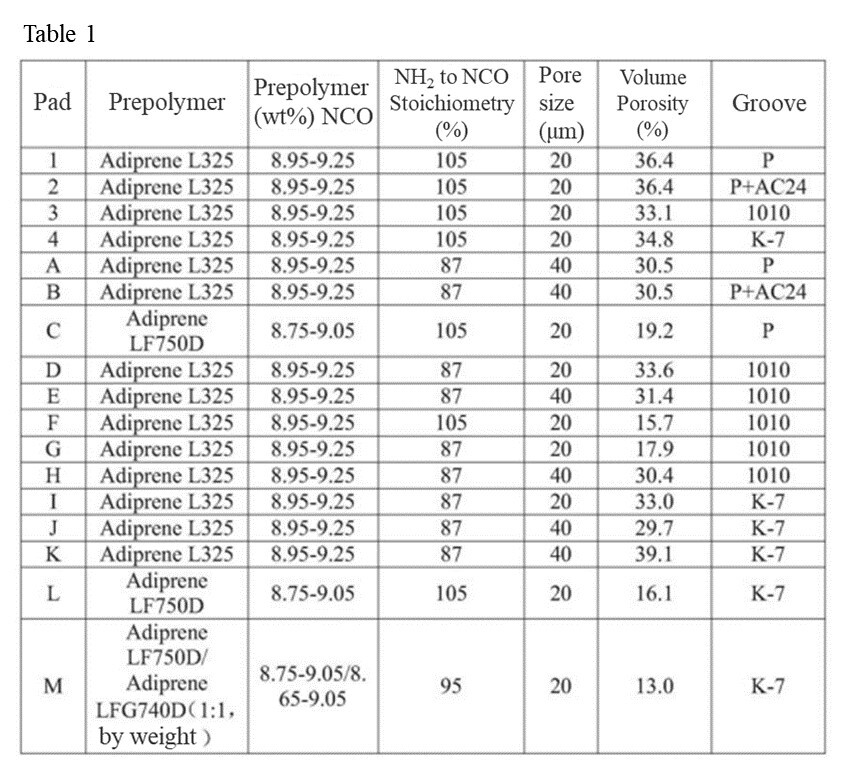

(1) Pads 1-4 shown in table 1 represent the technical means of the patent at issue. Pads 1-4 are illustrated to prove that the technical means have better polishing performances as compared to pads A-M:

However, table 1 simply shows parameters such as the prepolymer, the weight percentage of NCO in the prepolymer, the stoichiometry, etc. of pads 1-4. Neither the density nor the G′ and G′′ values measured in a non-porous state are disclosed. Therefore, table 1 cannot support the assertion that pads 1-4 fall under the scope of claim 1.

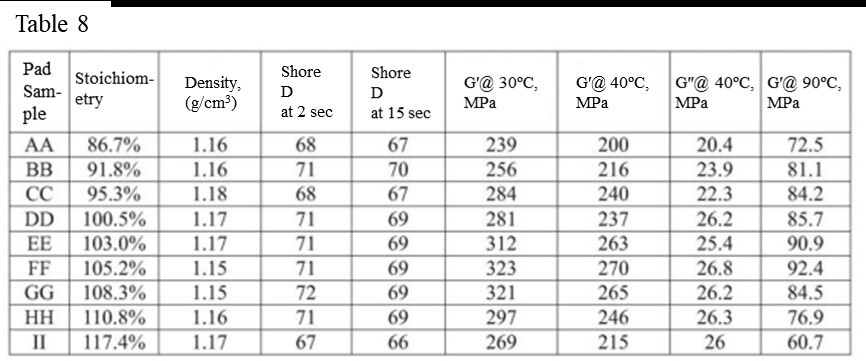

(2) Second, though Table 8 of the patent at issue contains information about the density, and G′ and G′′ values of pads AA-II measured in a non-porous state, it only shows the stoichiometry, without disclosing the prepolymer and its content of NCO. Therefore, it is also unclear which pad is within the scope of claim 1 merely from table 8.

(3) Furthermore, pads in table 1 and table 8 have different numberings. Given the ambiguous prepolymer adoption in Table 8, a person skilled in the art cannot ascertain that the pads in table 8 are made by the prepolymer falling within the scope of claim 1. Thus, there is no correspondence between table 1 and table 8.As a result, the patent at issue lacks solid experimental data to prove that the polishing technology in claim 1 has an unexpected effect.

(4) In addition, for the selection of prepolymer materials, listed on page 8 of the specification of exhibit 4 is a series of prepolymers to be selected from: “Adiprene® prepolymers LFG740D, LFT00D, LF750D, LF751D, LF753D, L325 purchased from Chemtura.” Therefore, , a person skilled in the art would have a motivation to select L325 to be the prepolymer, which means that the aforementioned distinct technical feature (1) has been disclosed by exhibit 4. And due to the fact that G′ and G′′ are determined by the diisocyanate, polyol, curative, and their quantity and stoichiometry in the raw material, the distinct technical feature (2) can be expected by a person skilled in the art as well.

(5) Lastly, the patentee argues that the patent at issue is directed to the removal of tungsten, while exhibit 4 does not mention anything about the removal of a metal. But still, a person skilled in the art, based on the teaching of exhibit 4, can alter parameters including the raw material, stoichiometry, etc. and thus obtain a polishing pad that is different from those disclosed in the prior art, since that there is no evidence in the patent at issue demonstrating that the limited technical features has brought about any unexpected effect.

Wisdom Suggested Strategies

In this case, the main problem of the specification of the patent at issue is that it lacks the experimental data including all of the limitations specified in claim 1. Examples in table 1 of the patent at issue illustrate that the technical effect can be achieved when parameters such as the prepolymer, weight percentage of NCO in the prepolymer, stoichiometry, etc. are in the range specified in claim 1. While examples in table 8 demonstrate that the technical effect can be achieved when G′, G′′, and the density are in the range specified in claim 1. Nonetheless, when presented this way, instead of the necessity of including both, it seems like as long as either "the prepolymer, weight percentage of NCO in the prepolymer, and stoichiometry" or "G′, G′′, and the density" is in the range specified in claim 1, the technical effect can be achieved.

However, the limitation on G′ and G′′ is the key distinction between the patent at issue and exhibit 4. Had the experimental data fulfilled all the limitations set forth by claim 1, it would have been able to prove the inventive step of claim 1 of the patent at issue. And yet, it is challenging to illustrate how the distinct technical feature "G′ and G′′" had contributed to the technical effect in the absence of such data. A person skilled in the art would have been able to obtain the invention of the patent at issue by selecting L325 as the prepolymer according to the examples in exhibit 4, and would have expected to achieve the technical effect of the patent at issue.

Additionally, the patentee argues that the use and effect of the patent at issue is different from that of exhibit 4, for exhibit 4 does not mention the removal of metal. However, the examination on the novelty and inventive steps of a product specified by use in Taiwan and China is stricter than that of Japan. According to section 3.2.5, chapter 3, part II of China Guidelines for Patent Examination, if the use is fully determined by the inherent property of the product and does not imply any change in the structure and/or composition of the product, the product claim defined by this use feature does not have novelty as compared with the product in the reference document. Taiwan Patent Examination Guidelines stipulate as well that, if the special use does not influence the product to be protected, but merely describes the purpose of or the way to use the product, the use does not furnish any effect for determining whether or not the claim involves novelty or an inventive step1. . Hence, although claim 1 is defined by the use of accelerating the removal of metal, the use does not influence the product to be protected, and therefore cannot serve as a distinct technical feature for the determination on inventive step.

In this case, the patent at issue can be deemed as selecting L325 among various materials, and selecting certain parameters among various process parameters. But, even when seen from the standpoint of a selection invention, the crux still lies in the fact that the patent at issue is unable to prove that the selection has led to an unexpected effect. Although the technical effect of the patent at issue and exhibit 4 is different, under the circumstance of insufficient experimental data, the difference is still deemed to be a common choice that a person skilled in the art can make to meet his purposes, which can be easily completed and lacks an inventive step.

[1]Section 2.5.4, Chapter 1, Part II of the Taiwan Examination Guidelines